We offer comprehensive custom manufacturing services to produce high-precision, complex parts.

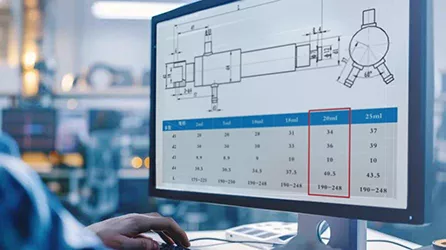

Experience in designing and developing custom advanced ceramic solutions for various applications.

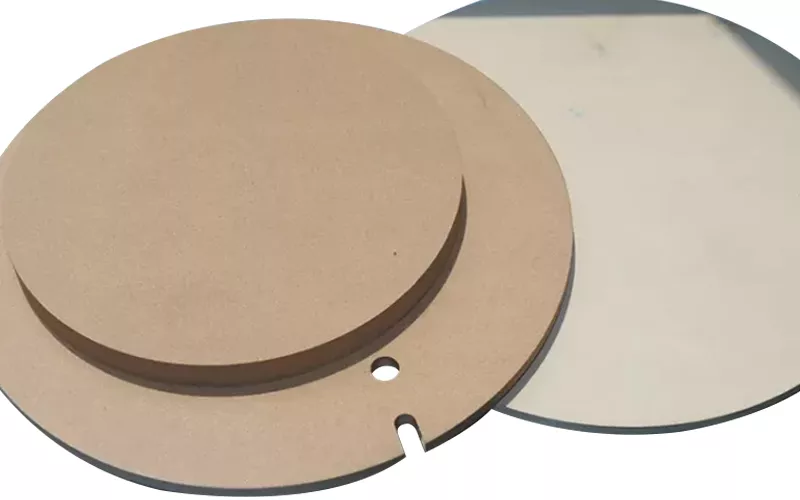

We have extensive experience in milling, grinding, and polishing high-precision technical ceramics.

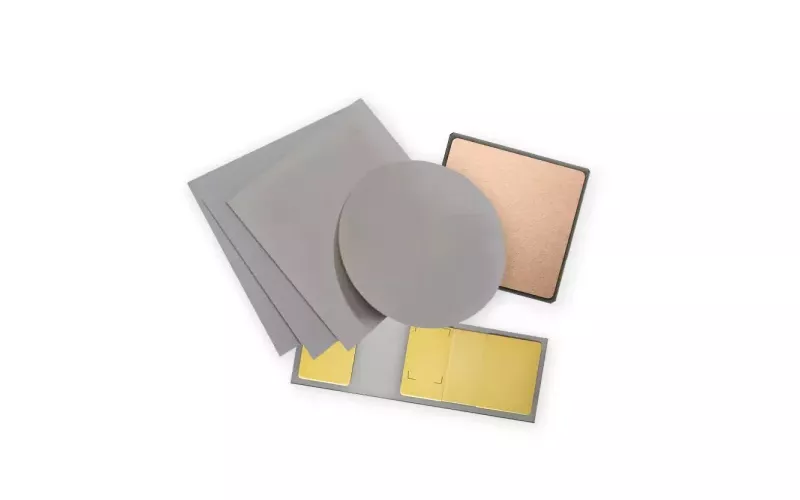

Customizable Ceramic Materials

We offer a wide selection of high-performance ceramic materials, including alumina, zirconium oxide, aluminum nitride, silicon nitride, boron nitride, silicon carbide, boron carbide, and beryllium oxide. GORGEOUS CERAMICS (GGS) will assist you in selecting the most suitable material solution based on your application requirements, achieving the optimal balance between performance and cost.

GORGEOUS Best-Selling Products!

We cater to the advanced ceramic needs of various industries. Whether your requirements include standard high-temperature and corrosion-resistant ceramic components, high-precision ceramic parts for the semiconductor industry, or ceramic heaters with fast response and high energy efficiency, we can provide you with proven, high-performance customized solutions, achieving a seamless transition from design to mass production.

Below are some of GORGEOUS CERAMICS (GGS) best-selling products!

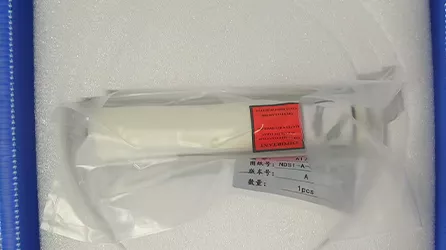

Ceramic Heater

Ceramic Igniter

Ceramic Substrate

Semiconductor Ceramics

Microporous Ceramics

Feedthrough

GORGEOUS CERAMICS (GGS)

– Your Trusted Partner

Products sold worldwide

Headquartered in China, GORGEOUS CERAMICS (GGS) exports its advanced ceramic products globally, aiming to provide customers with fast, high-quality, on-demand manufacturing solutions.

As a leading advanced ceramic supplier in China, we support global shipping, delivering to major regions in North America and Europe in as little as 3–10 days.

Our project engineers are all proficient in English communication. On weekdays, we respond quickly, seamlessly connecting with customer needs across time zones and ensuring smooth project progress from prototyping to delivery.

30,000㎡ 20,000+ 120+

Factory floor area Global customers The country of service

From New Product Development to Solutions

GORGEOUS CERAMICS (GGS) offers more than just manufacturing services. We provide full-cycle product development solutions, from design and prototyping to production and packaging.

Customized Advanced Ceramics For Different Industries

Our ceramic products have a wide range of applications, including aerospace, automotive, semiconductor electronics, machinery, chemical and medical fields.

Aerospace

Automotive

Electronics

Mechanical Engineering

Medical

Chemical

Our Ceramic Fabrication Applications

GORGEOUS CERAMICS (GGS) provides custom ceramic manufacturing to create structures, machines and parts including:

What Our Customer Say

GORGEOUS communicated very well with us, always understood our needs accurately and responded in a timely manner.

Karl

Their production speed is amazing, our orders are always delivered on time, the quality is excellent and it's a pleasure to work with.

SHE ZAN

We're really happy with their service! They sort out any issues right away, showing professionalism and efficiency. Big thanks to GGS!

Hans

Related Resources

Evaluating Thermal Management in Hexagonal Boron Nitride - Based Power Electronics

Introduction Hexagonal boron nitride is gaining significant popularity for its ability to efficiently manage heat in modern power electronics. Let’s explore their properties, benefits, how they improve thermal performance, and discover emerging trends, especially if you’re seeking better thermal management solutions. What is Hexagonal Boron Nitride? Diagram 1: Hexagonal Boron Nitride Hexagonal boron nitride (h-BN) is a special material made from boron and nitrogen. It’s a ceramic material with atoms arranged in layered hexagonal sheets. You can also refer to it as the hexagonal form of boron nitride. Commonly called “Graphite”, the most stable and soft polymorph of boron nitride. […]

Advantages and Uses of Boron Nitride Ceramic Sheets!

Learning about ceramic materials is inevitable if you are a materials scientist, engineer, or an enthusiast of modern technology. In this article, we discussed the advantages and uses of boron nitride ceramic sheets. Let’s dive in. What is a Boron Nitride Ceramic Sheet? The boron nitride (BN) ceramic sheet is a synthetic ceramic material formed into flat sheets. The BN sheets are also known as the boron nitride plate. The key elements of a boron nitride sheet are the inorganic boron nitride ceramic compound. The materials used in boron nitride ceramic sheet production are: hexgonal boron nitride powder(hBN) And additives […]

How to Use Electric Heating Tubes for Maximum Service Life: Safety Measures, DIY & Pro Tips

In this article, we’ll learn how to best use electric heating tubes in various contexts. Check in to learn DIY and professional tips for effective usage and maintenance! How To Use Electric Heating Tubes for Industrial Applications? 1. Set the Right Power-Input Voltage If your electric heating tube’s components keep failing, start by checking your voltage setting. Then set the power input voltage within 10% of your tube heater’s recommended voltage. This not only prevents premature failure of delicate components, it saves you from costly component replacements. You also get to avoid unnecessary hazards caused by electric shock. 2. Check […]

Submit a Quick Quote

Why GORGEOUS has the trust of 1000+ customers?

Our industrial ceramic manufacturing brings many benefits to various industries, businesses, or projects. Here are the advantages of our services.

Affordable and Fast Production

GORGEOUS can rapidly produce different ceramic prototypes and final products. GORGEOUS offers fast production while ensuring high precision. Our large-scale production also enables us to provide cost-effective ceramic manufacturing services.

Excellent Strength to Weight Ratio

Through our advanced fabrication technology, we can produce ceramic parts that are high quality yet durable. We assure high strength, scratch resistance, and corrosion resistance to all produced ceramic products.

Wide Range of Materials and Techniques Used

We are experts in different ceramic materials fabrication techniques that allow us to produce complex parts with additional intricate features such as notches, slots, holes, etc. Our wide range of ceramic materials can also withstand thermal resistance, corrsion resistance and more.